-

RINGLOCK SCAFFOLDING

RINGLOCK SCAFFOLDING APPLICATION With its flexible modular units and unlimited angular capabilities, the Ring Lock scaffold system makes it easy to scaffold a variety of complex building plans and elevations. In other words, it’s the go-to scaffold system for all applications in any type of indus...Read more -

The biggest Scaffolding manufacturer in China with high quality.

◆ High Standard Process: Q235 / Q345 ERW, three coating painting surface enhancing her corrosion resistance; 15 years lifespan. ◆ Multi-functional usage: Adapting to all kinds of construction requirements, especially suitable for the erection of scaffolding and heavy propping. ◆ Qui...Read more -

Pressed Scaffold Couplers

Scaffolding couplers are one part of tubes and couplers scaffold system. Their function is to fix two steel pipes so that a temporary platform can be erected for some construction purpose. Due to its flexiblity, it is widely used in petroleum & petrochemical projects, ship & aircraft main...Read more -

The biggest Scaffolding manufacturer in China with high quality.

WHY CHOOSE CUPLOCK SCAFFOLDING? ◆ High Standard Process: Q235 / Q345 ERW, three coating painting surface enhancing her corrosion resistance; 15 years lifespan. ◆ Multi-functional usage: Adapting to all kinds of construction requirements, especially suitable for the erection of scaff...Read more -

Cost-effective H20 wooden beam formwork for construction

H20 Wooden Beam Quick details: 1.Raw material: Pine LVL for Flange,Poplar Plywood for Web. 2.Glue:100% WBP Phenolic Glue. 3.Density: 5.0-6.0kg/M 4.Size:Flange 40x80mmxLength; Web: 27x150mmx Lenght; Height:200mm 5.Water Content: 5-12% 6.Lenght:1-12M avaliable. 7.Painting: Yellow waterproof paint...Read more -

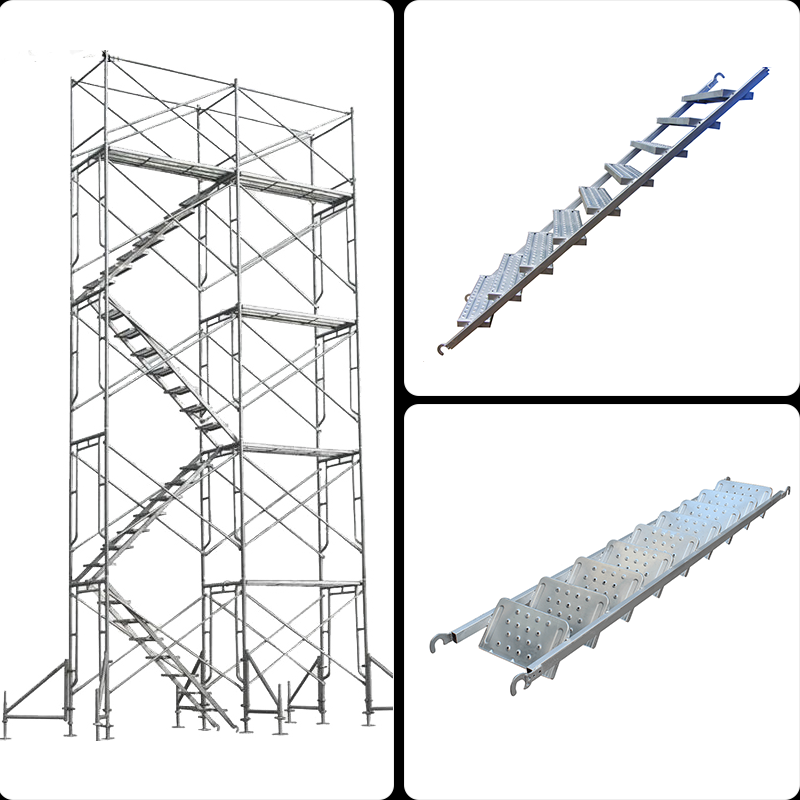

Scaffolding Steel Ladder

High Quality Scaffolding Stair Ladder World Scaffolding steel stair ladders are suitable for Frame scaffold, Ringlock scaffold system, Cuplock scaffold system and etc.Frame material: Galvanized steel tube Q235. Name Metal Stair Ladder Place of Origin Tianjin China Brand name ADTO Stee...Read more -

Cuplock Scaffold

Cuplock system is one of the main modular scaffolding systems. Its components include standard, ledger, intermediate transom, diagonal brace, side board support, beam bracket and cantilever beam frame. It is mainly used as internal shoring system. We monthly production capacity for cuplock system...Read more -

Scaffolding Frame Rolling Scaffold Tower Pre-galvanized

World Scaffolding Group have two types of Steel Frames. One is made by pre-galvanized steel pipes, mainly used in Southeast countries, Australia and Africa countries. The other type is made by black steel pipes and surface is treated with powder coating. These powder coating steel frames are very...Read more -

Adjustable steel prop

Adjustable steel prop is an ideal support equipment for construction, mine, tunnel, bridge, culvert and other construction projects. It is composed of inner tube, outer tubes, square plate, cupnut, G pin, adjustable collar, threaded tube, direct pin, etc. It has stable performance, free to adjust...Read more