-

Scaffolding Construction Essentials

Construction points: 1, the preliminary stage should do a good job of special construction program design of the support system, and by the general contracting unit positioning lines, so that the support system horizontal and vertical, in order to ensure that the later scissor braces and the over...Read more -

The main advantages of construction steel pipe fasteners are

1. This fastener is harmless. 2. The martensite organization of the hardened layer is fine, and the hardness, strength and toughness are higher. 3. After surface quenching, the surface layer of the workpiece has a greater compressive stress, the workpiece fatigue breaking ability is higher. 4. It...Read more -

Aluminum alloy type scaffolding advantages

1.It is easy and fast to install; equipped with high strength casters, it can be moved. 2. the overall structure adopts “building block” combination design, without any installation tools. Aluminum alloy quick release scaffolding solves the problem of working at height, it can be lapp...Read more -

Scaffolding maintenance details

1. Designate a dedicated person to conduct patrol inspections of the scaffolding every day to check whether the poles and pads have sunk or loosened, whether all the fasteners of the frame body have slide buckles or looseness, and whether all components of the frame body are complete. 2. Drain th...Read more -

Why choose steel prop on construction?

Steel prop, also known as adjustable steel prop, is mainly made of Q235 steel pipe, and the surface is treated by galvanizing, painting and powder spraying. The adjustment range of steel prop is divided into 0.8M, 2.5M, 3.2M, 4M or other special specifications. The range of use is also very wide,...Read more -

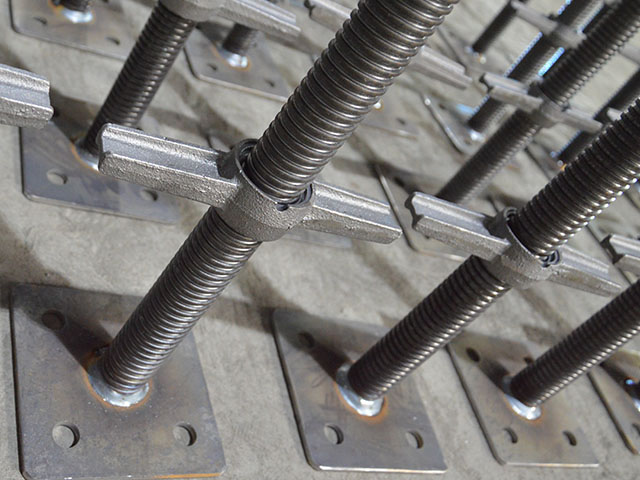

The Use of Base Jack in Scaffolding

The scaffolding base jack (screw jack) is used as the starting base of the scaffold, and provides stability by adjusting the jack nut of the base on uneven ground, and is used for level adjustment of the system scaffolding according to different underground heights. Adjustable base jack are also ...Read more -

Safety Technical Specifications for Bowl-Buckle Scaffoldings

The rod and inclined rod are inserted into the lower bowl buckle, press and rotate the upper bowl buckle, and use the limit pin to fix the upper bowl buckle. 1. The base and pad should be accurately placed on the positioning line; the pad should be made of wood with a length of not less than 2 sp...Read more -

Metal A Frame Scaffolding Features

One of the most popular scaffolding systems in the building business is certainly one with a tubular metal frame. The scaffold is made of cross bracing that connect welded steel or aluminum frames to build a framework for scaffold planks or other scaffolding platform systems. The most popular siz...Read more -

5 Reasons to use a ringlock system scaffold

5 reasons to use a ringlock system scaffold Ringlock scaffolding can be considered one of the most modern scaffolding systems in the world. We have summarised 5 of them for you here. 1. The ringlock scaffold offers you a high degree of flexibility and versatility With a ringlock modular scaffold,...Read more